Site managers hold everything together on a construction project. They handle materials and deliveries, keep an eye on health and safety, make sure everything stays legal, and push to keep the site running on time.

If these basics are overlooked, you could face hold-ups, accidents, or costs running over budget. Construction projects aren’t always smooth and straightforward, making it important for site managers to stay sharp, keeping track of every detail from start to finish.

In the middle of all that noise and movement, some minor bits are likely to be easily overlooked. A solid checklist changes that and lays out the must-dos while keeping the project on rails. In this article, we cover 5 of the many important items and tasks to cross off any site manager’s list.

1. Key Contractors and Supplier List

Every site needs a reliable lineup of contractors and suppliers locked in from day one. Delays in lining up the right teams lead to hold-ups, extra costs, and frustration across the board, so build this list during early planning and keep it ready to activate.

Start by identifying your core priorities. Whether it’s groundworks specialists for site prep and drainage or surfacing contractors like LSL Surfacing, based in Cambridgeshire, to align surfacing with the groundworks schedule, prepare the list with vetted contacts, quotes, availability windows, and key milestones. Review it weekly, chase confirmations, and have backups for weather or supply issues. A solid, prepped contractor roster ensures minimal delays.

2. Signage

Installing signage may not be the number one priority for site managers, but it’s an essential task to check off. The right signs and wayfinding can support efficiency and safety for everyone, from workers to delivery drivers to site inspectors.

More importantly, installing the appropriate health & safety and directional signage is required under UK health and safety legislation and site risk assessments. All mandatory signage needs to be clearly visible, correctly positioned, and relevant to current site conditions.

Sites must also have warning signs, prohibition signs, emergency signage, and mandatory instruction signs. Similarly, clear directional signage prevents drivers from entering unsafe areas, speeds up deliveries and drop-offs, and can skip the need to manually direct traffic. Bear in mind that the signages change as the site layout changes.

Flags add another layer for emphasising branding or marking key spots like entrances, show flats, or sales offices. Partner with some of the best online flag companies for custom designs that tie into your signs.

3. Site Welfare Units and Facilities

Welfare facilities are not only a legal requirement but also a key aspect of running a safe and productive worksite. Adequate and suitable welfare amenities for your workforce can also directly influence workforce morale and productivity.

For a compliant welfare setup, site managers need to make sure they follow the necessary regulations and requirements. Welfare provisions need to be accounted for right from the project planning stage to make sure appropriate facilities are available from day one. Key welfare requirements include sufficient, clean toilets, handwashing stations, clean drinking water, and areas for rest and meals. Ensure you choose the number and type of welfare facilities proportionate to the size of the workforce.

With welfare providers like Hireforce, site managers can choose from HSE-compliant, self-contained, independently functioning, mobile welfare facilities with quick setup times.

4. Core Construction Materials

Getting your construction material planning right is crucial to ensuring certainty in quality, cost, and delivery. Without adequate material and procurement planning, you risk project delays, rework, and site congestion.

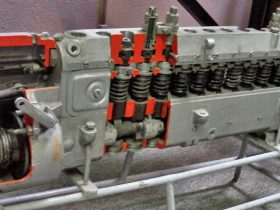

Aggregates are integral to most projects, from adding sub-bases and drainage layers to creating concrete and surfacing. But before materials arrive on site, site managers must confirm the correct type (sharp sand, ballast, or Type 3) and location and source of aggregates.

For example, for a site in Norwich or Dereham, site managers will need to source quality local Norfolk aggregates. It’s also important to confirm the volume required, including contingency allowances.

Other core construction materials include cement, steel, and wood. Coordinate properly with vendors and contractors to ensure the timely delivery of high-volume materials. Additionally, consider the impact of weather, transportation disruptions, or sudden demand fluctuations on the availability of core construction materials.

Site managers should also ensure proper storage and contamination prevention measures for construction materials, particularly for projects that span extended durations.

5. Site Access, Security, and Perimeter Control

Site managers are also responsible for controlling site security by managing access to the project site. Without these controls in place, your project may be at risk for theft, vandalism, safety incidents, and even harm to your project’s or client’s reputation.

Installing a secure physical boundary is the first step. From including perimeter fencing to lockable gates, these boundaries prevent unrestricted access while still allowing vehicular traffic. Next, know who is on site with mandatory sign-in and sign-out procedures, along with maintaining access logs for security and audit purposes. You can select between digital sign-in systems or paper-based logs.

The vulnerability of your site increases outside regular working hours. Keep theft, vandalism and unauthorised access incidents at bay by installing security measures. Consider installing adequate site lighting, CCTV on entrances and vulnerable zones, secured storage for materials, plants, and fuel, and alarm systems for high-risk zones.

As a site manager, ensure you clearly establish access and perimeter control before work begins.

Summing Up

This article covers five important things to cross off a site manager’s list. Additionally, it’s also important to account for groundworks and surface preparation, maintaining health, safety, and compliance documentation, managing plant, equipment, and machinery, waste management and environmental controls, contingency planning and risk management, quality control and inspection points, and handover preparation and site closure.

All in all, it’s the disciplined approach to planning your worksite that distinguishes a high-performing and smooth-running project site from an issue-prone one. These tasks are ongoing responsibilities, and site managers need to keep reviewing and modifying their checklist from time to time.