Step-by-Step Guide on Choosing the Right Fuel Injection Pump

The selection of an injection pump is not an accidental decision, and the process must include a systematic assessment of the correct matching of the chosen model to your engine requirements, both mechanically and electronically.

Determine the type of your engine and fuel system.

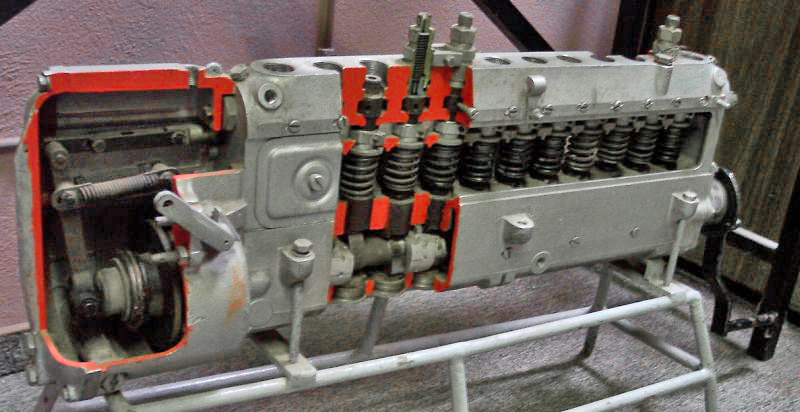

Get the necessary information about your engine-make and model, fuel system design (inline, distributor, common-rail, or HEUI), part numbers (where supplied by the OEM), and mechanical or electronic control-as outlined in a comprehensive Fuel Injection Pump Selection Guide. Diesel engines are designed with a certain timing, pressure, and control factor, and understanding these details helps ensure compatibility when selecting a replacement pump of any type.

Decide on New and Rebuilt Pumps.

When you are aware of your engine’s needs, then decide whether you would install a new injection pump or a rebuilt injection pump. The new pumps are long-lasting and have zero internal wear, and they meet the latest standards of emissions, which is why the new pumps are preferred in case of high demand or warranty. Rebuilt pumps offer an economical alternative to older models or lower hours of use and offer a quicker turnaround as long as they have been tested and match OEM calibration and flow requirements.

Find the Pump that Fits Your Application.

The fuel injection pumps are varied based on the use of the engine. Long-haul trucking vehicles require high-pressure, electronically controlled delivery and long intervals. Marine engines must have resistance to corrosion, and systems that are reliable in low-rpm consumption, whereas construction and agricultural equipment must have robust seals and require low maintenance. The pumps are designed to work during prolonged idle conditions with the advantage of emergency generators. The selection of a unit that is specific to such conditions will prevent early failure of the load in varying temperatures.

Know Calibration, Flow rate and Timing.

Contemporary diesel systems rely on a fine-tuning of the engine to maximise the fuel economy, emissions control and performance. Proper calibration of pumps will help to maintain the timing of injections in relation to engine cracks, avoid injector wear and tear and promote combustion efficiency. Ensure that the pump is bench tested under load conditions using real diesel fuel and also have detailed pressure and flow data to confirm that the pump has the correct performance profile.

Divide Lifecycle Cost, Not Purchase Price.

Consider the total ownership cost, including the risk of downtime, warranty period and the frequency of replacement although the initial cost matters. New pumps may be of longer service and lower risk over the long-run, but rebuilt pumps of high quality can offer a great value to cost-conscious projects.

General Fuel Pump Purchasing Blunders.

The errors include selecting a pump based on its surface condition, neglecting the calibration requirements, failure to match the specifications of the pump and injector, or buying a pump offered by non-expert sellers, thus causing premature pump wear and wasting money. Focus on professional checking of fit and functionality.

The Quality of Fuel and the Fuel Injection Pump That You Select.

The best pumps will not pump contaminated fuel well. Internal component premature wear is caused by water, microbial growth, low-lubricity diesel, and debris. Filtration and fuel quality are important considerations when choosing and maintaining a pump.

Will You Change the Fuel Injection Pump or Repair?

Minor problems such as leaks can be repaired, but the loss of pressure or internal scoring and electrical faults can typically be replaced or professionally reassembled.